Abstract: Stainless steel dowels are small yet critical components widely used across various engineering and manufacturing sectors. In this blog, we will explore what stainless steel dowels are, their types, manufacturing process, industrial applications, and benefits. By understanding their role, engineers and manufacturers can make informed decisions to enhance precision, durability, and overall product quality. Qihong provides high-quality stainless steel dowels suitable for diverse applications.

Table of Contents

- Definition of Stainless Steel Dowels

- Types of Stainless Steel Dowels

- Manufacturing Process of Stainless Steel Dowels

- Applications in Various Industries

- Benefits of Using Stainless Steel Dowels

- How to Select the Right Stainless Steel Dowel

- Frequently Asked Questions (FAQ)

Definition of Stainless Steel Dowels

Stainless steel dowels are cylindrical pins made from stainless steel that are used to precisely align or join two components together. They provide accurate positioning and secure fastening in mechanical assemblies. Commonly, dowels are used in machinery, electronics, automotive, and construction industries. Qihong specializes in precision stainless steel dowels designed for high accuracy and durability.

- Material: Typically 200, 300, or 400 series stainless steel

- Shape: Round, cylindrical pins

- Function: Positioning, aligning, and fastening components

Types of Stainless Steel Dowels

There are several types of stainless steel dowels, each suited for different applications:

| Type | Description | Typical Applications |

|---|---|---|

| Solid Dowel Pins | Precision-ground solid pins for accurate alignment | Machinery, automotive, electronics |

| Hollow Dowel Pins | Lightweight pins with hollow cores, often used for weight reduction | Aerospace, robotics, lightweight machinery |

| Threaded Dowel Pins | Dowels with threads to facilitate easy installation and removal | Mechanical assemblies, fixtures, molds |

| Grooved Dowel Pins | Pins with grooves to hold lubricants or adhesives | Industrial machinery, hydraulic systems |

Manufacturing Process of Stainless Steel Dowels

The production of stainless steel dowels involves multiple precise steps to ensure high quality:

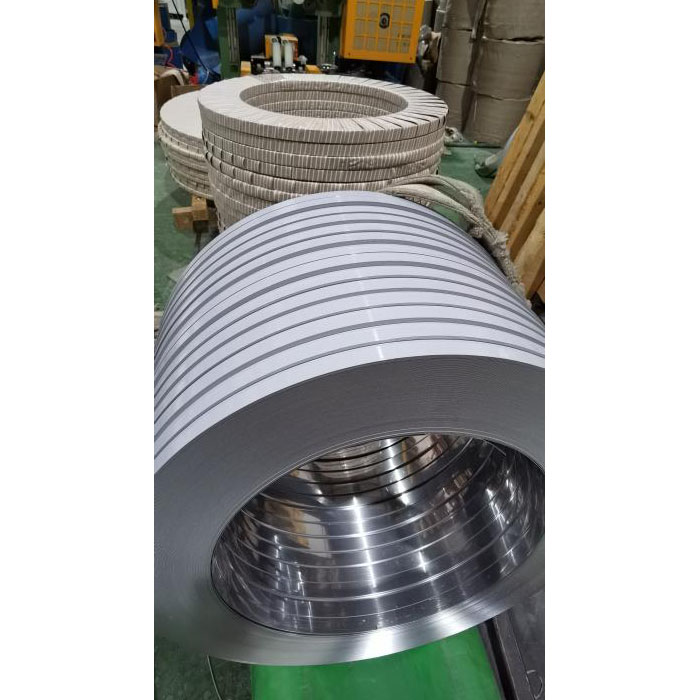

- Material Selection: Choose appropriate stainless steel grade (200, 300, 400 series) depending on corrosion resistance and mechanical strength requirements.

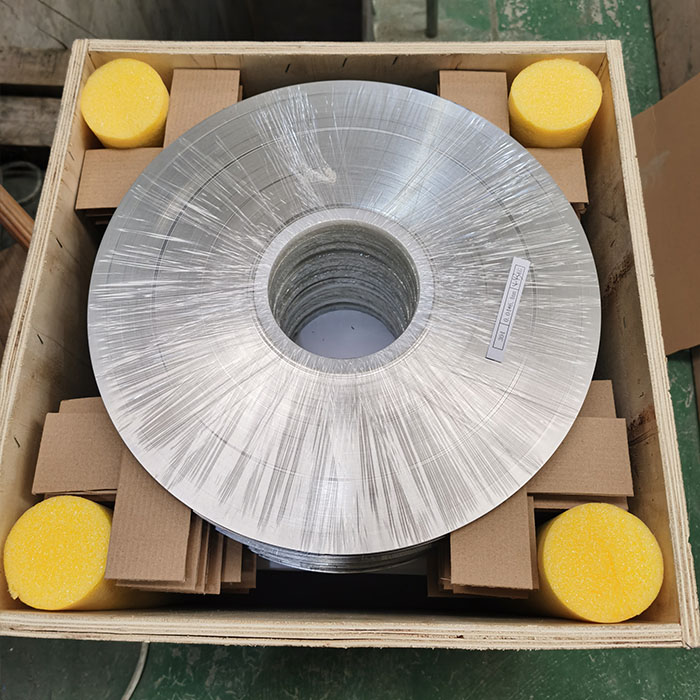

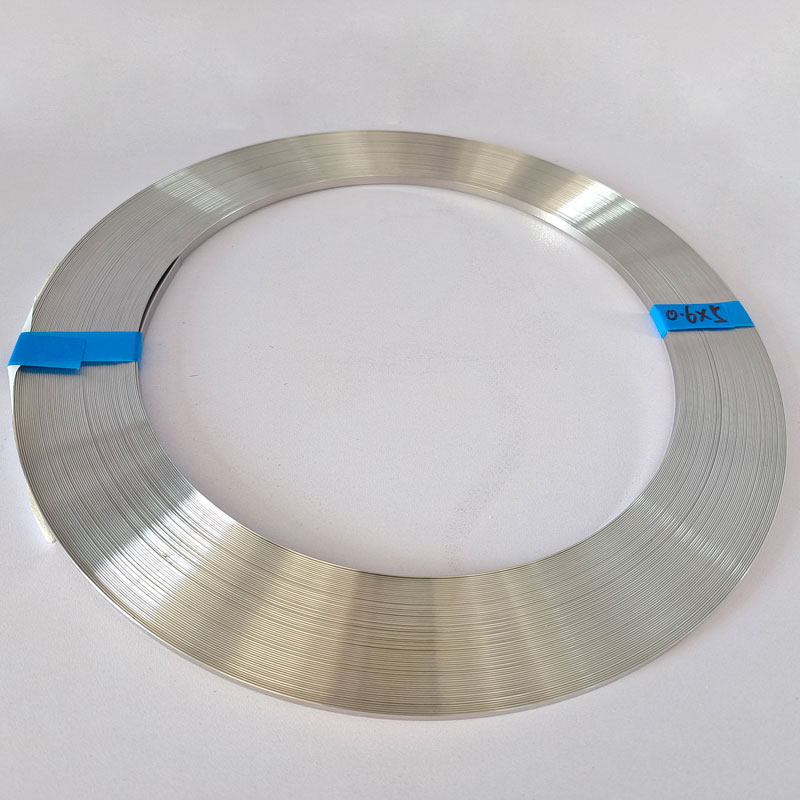

- Cutting and Shaping: Stainless steel rods are cut to the required length and shaped into cylindrical pins.

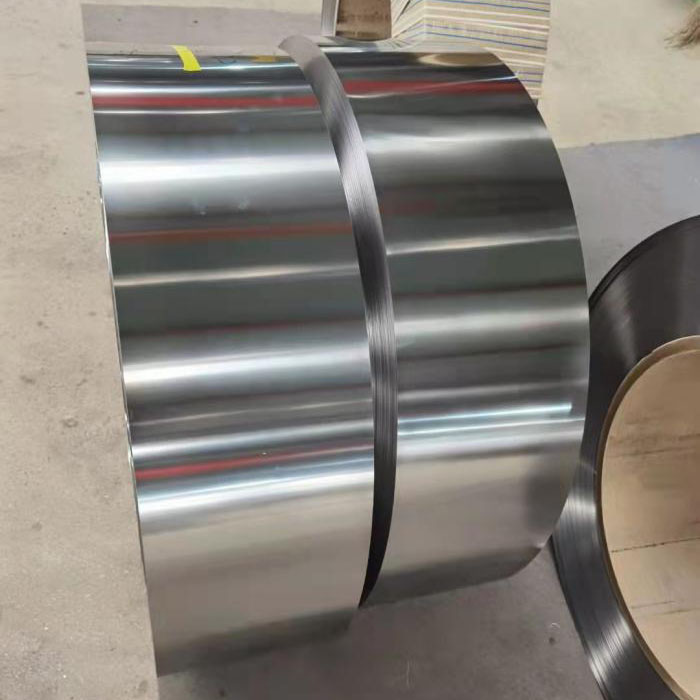

- Cold Rolling/Grinding: Dowels are precision-ground or cold-rolled to achieve tight tolerances and smooth surface finish.

- Heat Treatment: Optional hardening process for increased strength and durability.

- Quality Inspection: Dimensional checks, surface roughness testing, and material certification to ensure compliance with engineering standards.

Qihong utilizes state-of-the-art production equipment to deliver high-precision dowels suitable for diverse industrial requirements.

Applications in Various Industries

Stainless steel dowels are versatile and can be found in numerous industries:

- Automotive: Alignment of engine components, chassis assembly, and precision fastening

- Electronics: Positioning of circuit boards, connectors, and button batteries

- Home Appliances: Washers, dishwashers, and cookers use dowels for precise assembly

- Construction: Structural components, wall decorations, and stainless fixtures

- Medical Equipment: Precision alignment in devices and surgical tools

Benefits of Using Stainless Steel Dowels

Using stainless steel dowels in mechanical assemblies offers several advantages:

- High Precision: Ensures accurate alignment between components

- Durability: Corrosion-resistant stainless steel provides long-lasting performance

- Easy Assembly: Reduces installation errors and assembly time

- Versatility: Applicable across multiple industries and applications

- Cost Efficiency: Reduces maintenance and rework costs

How to Select the Right Stainless Steel Dowel

Choosing the appropriate stainless steel dowel depends on:

- Material Grade: Select 200, 300, or 400 series based on strength and corrosion requirements

- Size and Tolerance: Ensure proper fit for precise alignment

- Type of Dowel: Solid, hollow, grooved, or threaded according to the application

- Surface Finish: Smooth surfaces reduce friction and wear

Qihong provides customization services to manufacture dowels according to exact technical drawings, ensuring optimal performance for each project.

Frequently Asked Questions (FAQ)

1. What is the difference between solid and hollow stainless steel dowels?

Solid dowels offer maximum strength and rigidity, while hollow dowels are lightweight and suitable for applications where weight reduction is important.

2. Can stainless steel dowels be used in high-temperature environments?

Yes, certain grades such as 300 series stainless steel are suitable for high-temperature applications.

3. How does Qihong ensure the precision of its stainless steel dowels?

Qihong uses advanced grinding, cold-rolling, and inspection equipment to maintain strict tolerances and high-quality standards.

4. Are custom sizes available?

Yes, Qihong provides customized stainless steel dowels based on client specifications or technical drawings.

5. What industries commonly use stainless steel dowels?

Industries include automotive, electronics, home appliances, construction, medical devices, and energy equipment.

If you want to ensure maximum precision and durability in your assemblies, Qihong stainless steel dowels are your trusted choice. Contact us today to discuss your project requirements and request a quote.