The food processing industry uses 321 stainless steel coils mainly because of its key properties:

1. Excellent corrosion resistance

321 stainless steel contains titanium, which makes it more resistant to corrosion in high temperature environments against acidic foods, salts, and other chemicals in the food processing process. The addition of titanium enhances its resistance to intergranular corrosion, making it suitable for long-term exposure to wet, acidic or alkaline environments.

2. Good high temperature resistance

321 stainless steel coils can maintain its structure and performance in high temperature environments and can usually work normally at temperatures between 700°C and 900°C. In the food processing process, especially in high temperature operations such as baking and steaming, 321 stainless steel exhibits high heat resistance, making it very suitable for equipment and tools that need to withstand heat changes, such as ovens, steamers, food conveyors, etc.

3. Anti-oxidation

The titanium element in 321 stainless steel can effectively prevent oxidation at high temperatures, making it less likely to rust on the surface when exposed to air for a long time. This is especially important for the food processing industry, where food contact surfaces need to be kept clean and sanitary to prevent metal rust from contaminating food.

4. Better processing performance

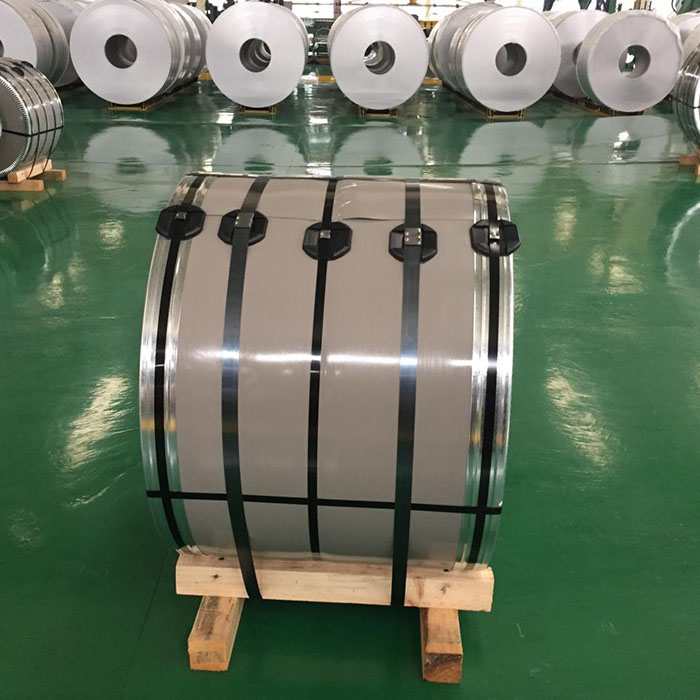

321 stainless steel has good formability and weldability, which means it can be easily processed into various shapes and sizes, such as coils, plates, pipes, etc. For the food processing industry, the manufacture and repair of equipment often require a high degree of customization, so the ease of processing of this material is a major advantage.

5. Food safety

Due to the corrosion resistance and high temperature resistance of 321 stainless steel, it can effectively avoid reactions with food during food processing and ensure food safety. Food processing equipment requires strict hygiene standards, and 321 stainless steel meets this requirement without releasing harmful substances.

6. Anti-intergranular corrosion

Titanium can effectively prevent intergranular corrosion caused by high-temperature operation, especially in welding or high-temperature working environments, which is particularly important for high-temperature operation in the food processing industry. The prevention of intergranular corrosion can increase the service life and work efficiency of equipment.

Summary:321 stainless steel coils has become a widely used material in the food processing industry due to its corrosion resistance, high temperature resistance, oxidation resistance, good processability and resistance to intergranular corrosion. It is particularly suitable for occasions that are in contact with food for a long time and need to withstand high temperature or chemical corrosion, such as ovens, processing equipment, pipelines, etc.